Processes

The purpose of the COPEG Sterile Fly Plant is the mass production of sterile Screwworm flies required for the prevention and eradication of this disease.

Production

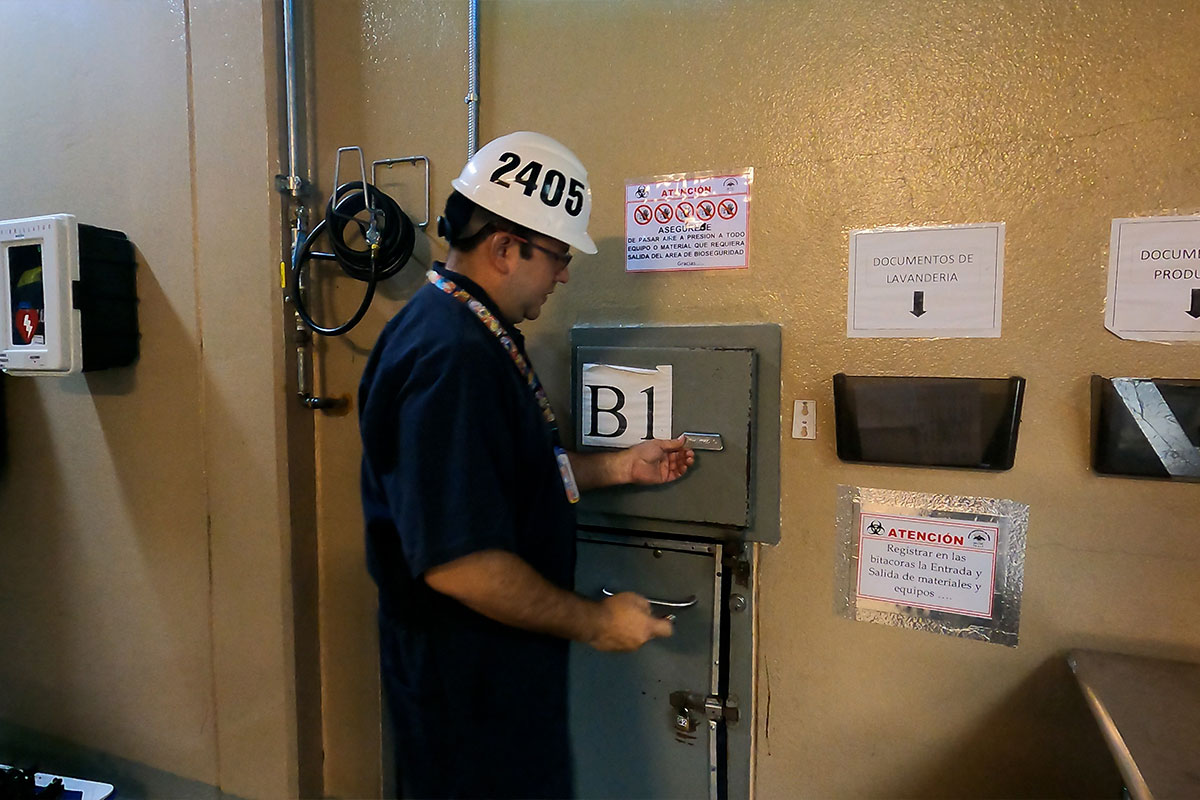

The production process within the plant is designed to artificially replicate the life cycle of the Cochliomyia hominivorax fly. The plant was inaugurated in July 2006 and follows BSL biosecurity protocols with Levels 2 and 3 characteristics, ensuring that fertile screwworms cannot escape from the facility.

For mass rearing, the screwworms are fed an artificial diet and kept in controlled environments that simulate natural conditions. This allows full control over the insect’s life cycle—from egg, larva, and pupa to adult—ensuring optimal production and meeting the requirements for dispersal within the biological barrier.

The plant is designed to produce up to 100 million sterile pupae per week and is composed of several specialized departments:

Process

Cage Setup

Oviposition

Egg Collection

Egg Hatch Rate Measurement

First Larval Feeding

Second Larval Feeding

Transfer of the Insect to the Drop Room and Collection

Larvae Collection

Transformation into Pupa

Maturation Room

Process

They house 6 liters of fertile pupae to ensure the continuity of production. In this space, the flies reproduce, and egg laying is expected to occur after 7 days.

After this period, the cages are moved to the oviposition area, where, under specific conditions, egg laying begins and lasts between 6 and 7 hours.

The eggs are placed on moist paper for incubation and are sustained with a special diet that simulates a warm-blooded wound (5 liters of diet daily).

It is carried out 10 to 12 hours later.

It takes place after 36 hours of incubation and consists of 8 liters of diet.

It occurs 72 hours after incubation and consists of 7 liters of diet.

Transfer of the Insect to the Drop and Collection Room: In this area, the insects will remain for 4 days.

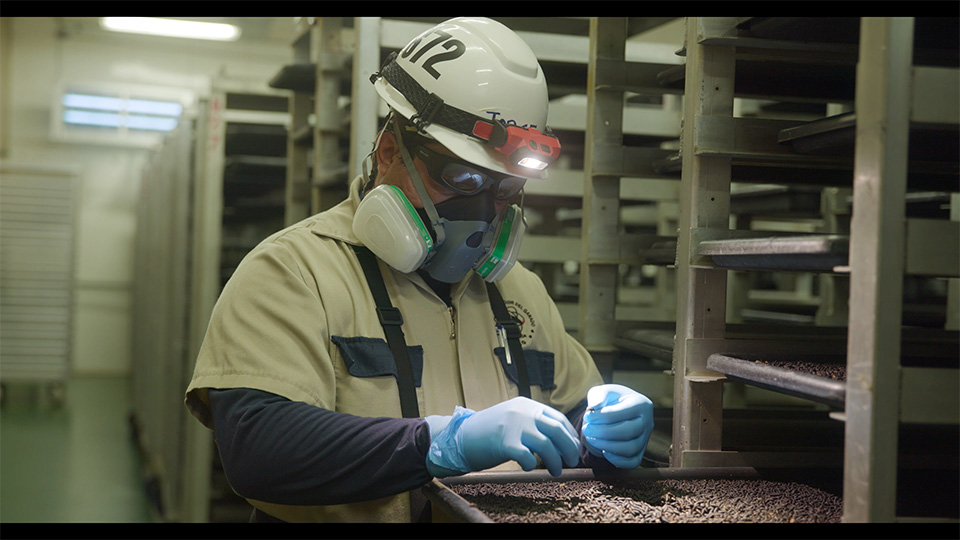

It is carried out every 4 hours. In this step, 3 liters of larvae are distributed into trays with 6 liters of sawdust to simulate the natural process of falling to the ground.

It takes place 24 hours after collection, during which the pupae are separated from the sawdust using a sifter.

This is the space where the trays of pupae are transferred. Here, they are organized and labeled according to their maturation time.

Complementary

Breeding Stock:

This process takes place during the larval stage and involves collecting 8 liters of larvae per shift to maintain the strain and production cycle. During maturation, these larvae are not sterilized, as they must remain fertile to be used in cage setup and egg production.

Insect Measurement:

This is carried out at the end of each feeding, collection, and sifting process to monitor and control the insect’s growth.